Category: Quality Control

All aspects of quality control in the brewing of craft beverages

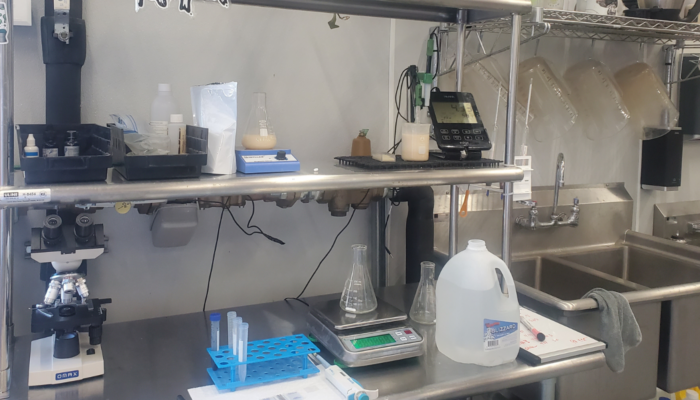

Expert Topic Assessing Lab Needs, What You Need, What To Wish For

Starting a brewery is an exciting, nerve-wracking, whirlwind experience for many, with much of the focus on finding the perfect location, keeping costs down during buildout, and crafting recipes and brand identities. Breweries also need to keep an eye on beer quality as the competitive beer marketplace won’t support off-flavors and aromas for long. That means focusing efforts on critical but less visible operations, such as testing your brewery’s beer.

(more...)

News BA Addresses Safety of Non-Alcoholic Draft Beer

The rising popularity of non-alcoholic beer has prompted many brewers to consider entering the category. But concerns have risen recently over the prospect that non-pasteurized beer without the natural protection of alcohol may be subject to the growth of pathogenic bacteria, and a significant health risk to consumers.

(more...)

Sponsored Fermentation Analysis – Understanding Free Amino Nitrogen (FAN)

Free Amino Nitrogen (FAN) is a critical parameter in beer analysis that leads to a healthy fermentation, and thus better beer quality. It is a measure of the concentration of amino acids and small peptides that are essential for yeast metabolism. In simpler terms, it is an indicator of the amount of food that is available for yeast, helping them convert sugar into alcohol during the brewing process more effectively.

(more…)

Sponsored QC, Scheduling & Flexibility: Software Strategies for Success with Randy Smith of Vicinity Software

In the beginning of a brewery’s life span, the ownership and employees juggle several tasks and responsibilities across departments. Using the proper tool to store your data will take you a long way in your growth. But what you started using in the beginning may be missing the mark now.

(more…)

Sponsored Increasing Brewery Efficiency and Beer Quality with Production Data with Brynn Keenan of Grist Analytics

Production data is one of the most under-utilized assets in craft brewing. With a relatively minor amount of work, this data can be used to increase throughput, efficiency, raw material extraction, and beer quality. Learn how to utilize your production data through statistical process control, and turn it into something valuable.

(more…)

Sponsored Documenting Beer Flavor for the Professional Brewer

No matter how often we drink a beer, it’s not often we actually taste it. Our palates are the most critical instrument at our disposal, yet they are often underutilized or misused. How can you use lab techniques and instrumentation in conjunction with your senses to develop a quality assurance program for your brewery?

(more…)

Expert Topic Setting Up a QC Lab with Neva Parker of White Labs

My favorite part of any brewery tour is seeing the lab. It’s not that I’m a science nerd or even particularly conversant in what goes on in these scientific sanctuaries. A lab is a sign that a brewery takes quality serious enough to invest resources in pursuit of it.

(more...)

Sponsored Using Fermentation Profiles to Improve Your Recipes with Pål Ingebrigtsen of PLAATO

Brewing is the perfect mix of science, creativity and craftsmanship. For many brewers, creating and improving on recipes, while maintaining a high quality product is a big part of their daily work. When brewers start to collect ongoing fermentation data across multiple batches over time, they can compare how small tweaks in the recipe or outside conditions can change the overall outcome of the fermentation.

(more…)

Sponsored Making the Most of Your Malt with Riley Aadland of RMS Brewing Solutions

This presentation focuses on giving a deeper dive into an often times misunderstood and undervalued part of the brewing process – the grist. Preparing the grist for mash in is the first step in the brew day and is a vital part in ensuring that the system is as efficient as possible from the very beginning. We will talk about the tools needed to do a grist analysis, how to go about doing the grist analysis to get accurate results, interpreting those results, and what to do with the data once you have it.

(more…)

Expert Topic The Importance of and How to Read your Water Report

The make-up of water will vary, over time, with any municipal water system. To ensure good consistent brewing water that will produce a better product and a consistent product, knowing what is in your water is essential. Today, knowing that you can control the water make-up, right before brewing, allows you to control the taste and look of your brews.

(more...)