Workhorse ABE GlassPak 33 Bottle Filler, Infeed Table, Air Knife, Set up for 12oz Bottles ( $35,000 )

Used Product Ad posted 3 weeks ago in Bottling Equipment by Cory Johnston

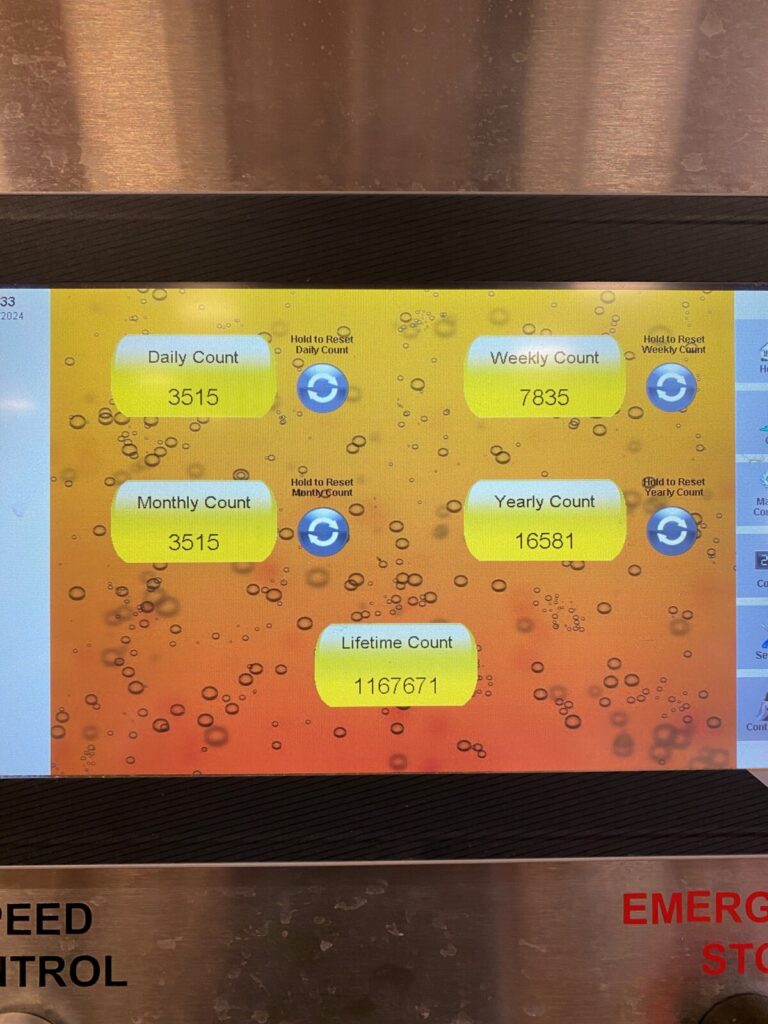

This machine is currently being used weekly and will be decommissioned in June 2024. Purchased new from ABE and commissioned in 2020. The 12 head filler, ABE GlassPak33 has been a workhorse for our brewery and has been well maintained. We are selling the infeed turntable, GlassPak33, air knife, and crown hopper/conveyor. We run the system at 33 bottles per minute (1,980/hr) and average loss levels of 3%. It’s currently set to fill 12oz stubbie bottles and can easily be configured to run other 12oz bottles (heritage, long neck, etc). We also include changeover parts for filling 500ml Euro style bottles.

Here is some information from the manufacturer, ABE, who is also super reliable for parts, advice, and auxiliary equipment.

48” Rotary Glass Bottle Feed

A group of glass bottles is placed onto the table’s in feed chute. Bottles are then

pushed onto the rotating table and delivered to the Monoblock system . These bottles

will begin to enter the exit lane of the feed table and travel onto the main feed

conveyor in a single file. Those bottles that do not enter the exit lane travel around

the table and accumulate against the bottle return assembly. This process is

continuously repeated when bottles are in demanded.

GlassPak33 Rinse/Fill/Crown

Built with a heavy-duty stainless steel frame and stainless steel main platform, the GlassPak33 is ready for action when it reaches your brewery. (“Monoblock” Filling Systems are

robust, continuous motion systems, designed to streamline the rinsing, filling and

capping process while minimizing valuable floor space).

Operating Features of the GlassPak33:

Bottle Feed Conveyance:

Empty bottles are loaded onto an optional Feed Table or directly onto the main Feed

Conveyor to be transported into the Monoblock station.

Pre-rinse

After being conveyed into the Monoblock unit, bottles are automatically inverted,

rinsed and drained to release any debris that may have accumulated during bottle

transportation or storage.

In this phase, the continuous motion design, grabs and inverts each bottle and

positions it over an internal rinse nozzle spraying water, or sanitizer solution, inside

the bottle. Typical installations use tap water for pre-rinsing and then run the used

water to a drain. The “GlassPak33” also comes with a recirculating pump that allows

the brewer to recycle a sanitizing rinse solution if so desired.

Bottle Filling

The GlassPak33 is an 12 head, counter-pressure style bottle filler with

Double-Pre-Evacuation Feature. Each head performs four main functions during the

filling process: 1). Removing the majority of air from the empty bottle 2). Purging and

pressurizing the bottle with carbon dioxide 3). Filling the bottle with beer; under

pressure. 4).Relieving the pressure and releasing the bottle to complete the filling

process. After rinsing, bottles travel to the filling station where air is vacuumed from

the inside of the bottle to maximize oxygen removal. When the fill valve is opened,

any remaining air is replaced with Carbon Dioxide-CO2 at an adjustable pressure of

up to 40psi. This process helps to ensure low dissolved oxygen carryover, which

increases shelf life and maintains quality. Once bottles have reached the same

internal pressure as the Filling Drum, a spring activated device allows the liquid valve

to lift from its seal and initiate the filing process. The fill level of each bottle is limited

by a predetermined fill-vent tube length. The lower this tube protrudes into the bottle,

the lower the final fill level position. Once the rising liquid reaches the vent tube, it

travels up the tube until it reaches equilibrium with the liquid in the drum which forces

all liquid movement to stop. The filling valve is then closed; an exhaust port is

opened and the bottles are “vented” until there is no longer counter-pressure inside

each bottle. After this process is complete, bottles travel to the capper where a

crown cap is automatically applied.

Capping

The capping portion of the system elevates bulk caps (the hopper will hold up to

5,000 crown caps) from the hopper to the Cap Unscrambler. The Unscrambler

tumbles caps in a protected chamber that directs them to the main Cap Chute

Assembly with the open side up. At the bottom of the chute, a small air stream blows

each cap into the capping position in preparation for proper application. As bottles

pass under the chute, caps are applied by way of a Tapered Ceramic Sleeve that

forces each cap onto the top of the bottle forming the hygienic seal.

GlassPak Specifications:

” Production speeds up to 33 bpm based on 12 oz. bottles.

” Power: 208 – 240 volt 3 phase, 60 hz.

” Amp draw: 30 amps – including “optional” dryer.

” Adjustable machine speed based on production needs and manpower available.

” CIP Compatible

” Air Pressure requirements – Minimum 90 psi @ 10 SCFM

Stainless steel main Platform. Main waste drain. Power use less than 30 amps

including “optional” dryer.

208/240 volt 3 phase, 60 hz. Adjustable speed control. From 1000 to 2000 bph

depending on available labor or carbonation level of select beer. Adjustable machine

speed based on manpower available. Less than 2% beer waste. 3 gl. per minute

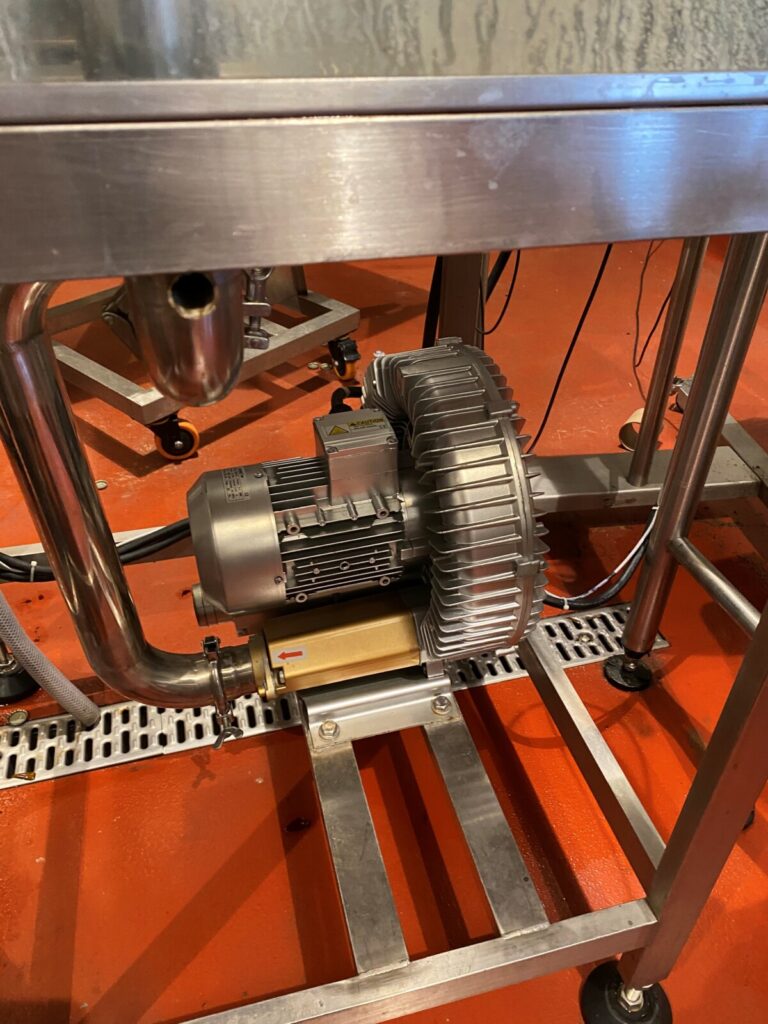

waste water for pre and post-rinsePost-Rinse Bottle Dryer

To reduce cost of using compressed air to dry bottles, an Optional Centrifugal Air

Blower coupled with Adjustable Air Knives is available. High volume air is supplied by

the built-in centrifugal blower to remove majority of water from outside of bottles prior

to labeling. The Dryer includes; stainless steel construction, central electronic

controls, central drain lines and 2 removable clear side-panels for visual monitoring

and accessibility. Post-Fill Rinsing Option

The “GlassPak” also offers a Post-Fill Rinsing Option to rinse bottles as they leave

the Monoblock unit. Horizontal water jets in this post-fill rinsing stage ensure beer

residue is removed from the exterior of the bottle as well as the underside of the cap.

- Manufacturer : ABE

- Original Manufacture Date : 2019

- Where Manufactured : USA

- Ships From : Lawrence, KS, USA