Starting a brewery is an exciting, nerve-wracking, whirlwind experience for many, with much of the focus on finding the perfect location, keeping costs down during buildout, and crafting recipes and brand identities. Breweries also need to keep an eye on beer quality as the competitive beer marketplace won’t support off-flavors and aromas for long. That means focusing efforts on critical but less visible operations, such as testing your brewery’s beer.

Brewing Equipment featured expert topic supported by Chart Industries

Chart’s LN2 dosers support container pressurization and TPO reduction, and Earthly Labs’, SES’ and Howden’s carbon capture and compressor solutions enable breweries to capture CO2 emissions during fermentation process, boilers, or anaerobic digesters and reuse it onsite. ChartWater™ utilizes high recovery and low-energy water and wastewater treatment technologies, including the optimization of water reuse for sustainable, market-leading solutions.

When you begin to think about designing a laboratory for a new brewery–hopefully before you open–it’s important to keep in mind that the lab doesn’t need to be stocked with hundreds of thousands of dollars of equipment and tests. Instead, it’s important to ask some basic questions. What analysis will you perform on your beer? What equipment will you need to perform the tests? Will there be a dedicated lab person or will existing staff conduct the tests? Will there be dedicated space for the lab? Focusing on key areas, such as assessing microbiological contamination, checking yeast health, conducting routine sensory analysis, and analyzing batches of beer to calculate alcohol and IBU levels or to check for diacetyl, acetaldehyde, and other off notes, are musts.

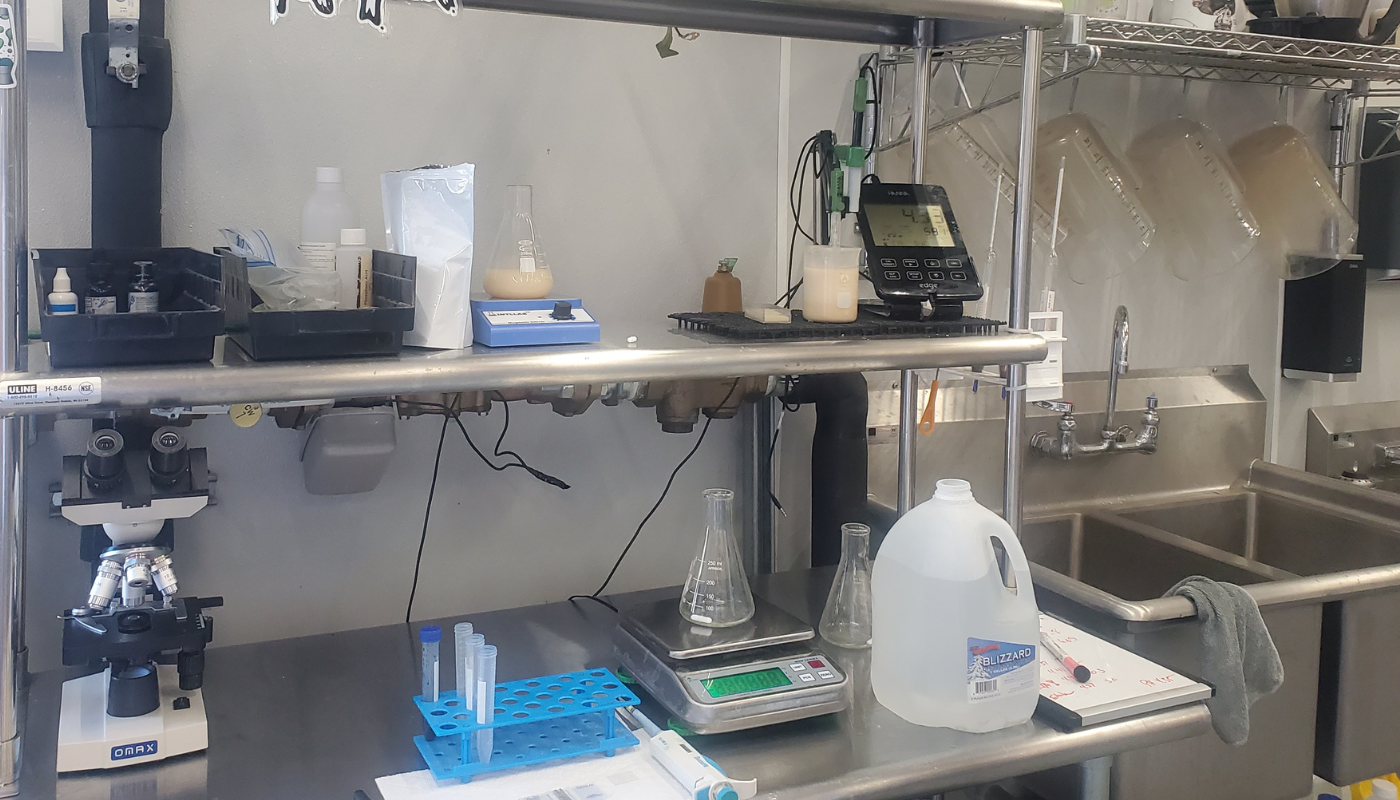

In designing the lab space, considerations include the number and location of sinks, space necessary to wash items by hand, adequate countertop space for equipment and other testing implements, and areas for storage of both refrigerated items and ambient materials. You will also need to check with local authorities to understand and comply with local building codes and regulations covering laboratories.

There are some items you should consider purchasing for a start-up brewery lab. Some items are simple, such as a thermometer, shelving for archived packaged beer, refrigerators and coolers. In the chemistry department, you’ll need a hydrometer to measure the gravity of finished beer and to check on the status of fermentation, a pH meter to confirm the acidity levels, and a CO2 meter to check dissolved carbon dioxide levels especially if you’re canning beer, and a low-range oxygen meter to check dissolved oxygen levels in brite and packaged beer. In terms of microbiology, startup and small breweries need a microscope to check yeast cell counts and look for the presence of bacteria, and a hemocytometer to conduct yeast cell counting, health, and to assist in dialing in pitching rates. For sensory analysis, investing in training for employees can be as easy as signing up for a webinar series and investing in flavor standard spiking items and a calculator.

As your brewery grows, so will your lab needs and brewery lab needs often depend on the size of a brewery. Many organizations, such as the Brewers Association and the American Society of Brewing Chemists (ASBC) provide easy to follow charts and guides for scaling up your equipment and testing needs as your brewery increases its production. When breweries exceed 10,000 barrels of production, investing in other lab items should commensurately increase. Purchasing software to help run the lab and maintain data will help control processes and streamline outflow. Breweries will consider individual equipment purchases and weigh their cost and utility. Common items in larger breweries include an alcohol meter, spectrophotometer, centrifuge, and gas chromatograph.

Teri Fahrendorf has authored a smart and easy to digest guide for small brewery lab procedures. A longtime brewer at Steelhead Brewing, Triple Rock, and others, Fahrendorf founded Pink Boots and consults with breweries. Her guide lists supplies needed for setting up a lab, down to the number of test tubes, pipetters, and flasks. It has a very do-it-yourself feel for those breweries looking to save on laboratory setup costs. She even hacks together an incubator built from a picnic cooler, complete with photos and a rudimentary hand-drawn installation guide and designs. Fahrendorf also includes sample test logs, and advice for conducting testing and analyzing results.

One critical area breweries should focus on building out is sensory analysis. In the beginning, setting up a basic sensory program can help develop the skills of the team as well as protect the brewery against flaws in batches. Many organizations, including the BA, the Siebel Institute, and others offer basic training, both in person and on the internet, making it easy to teach staff how to conduct and participate in the sensory analysis exercises . In addition, suppliers often offer training on assessing the quality of ingredients including malts, hops, and yeast, and how to analyze them both as they arrive at the facility and as they’re used in production.

The BA has released several education items related to creating a sensory panel. The guide notes the importance of having staff regularly taste the product at every stage of production and that individuals can exhibit bias in conducting sensory analysis. To account for this, the BA recommends that sensory analysis programs take a “methodical and deliberate approach” to testing to allow breweries to produce beers free of off-flavors and to maintain their true-to-brand character. In the absence of hiring a professionally trained sensory scientist, breweries of all sizes should designate an individual to lead the analysis program. The company can then invest in training and educating this individual to better run things. The tasting supervisor should set up the program, including maintaining and doctoring samples with known off-flavors. Breweries should also train as many panelists as possible–as every taster has different abilities and sensitivities–to give the facility the best chance of catching any problems. Relying on sensory analysis conducted by a single individual, especially the person brewing the beer, is a recipe for problems. With different palates sensitive to compounds and aromas at different levels and brewers prone to bias towards their own products, rigorous and well-planned training programs don’t require much equipment but serve as a critical failsafe before releasing beer to the public.

As breweries grow, they may also expand their tasting and sensory testing areas to better control conditions and keep individuals separate to avoid bias. Setting up separate sensory booths can eliminate distractions, controlling for noise, aromas, and other irritants.