Decanter Centrifuges in the Brewing Process

Flottweg Separation Technology Case Study

When most people in the brewing industry hear the word centrifuge, they immediately think of the usual vertical, high speed, disc stack clarifier type that most breweries use. Traditionally for final clarification or turbidity adjustment (think cloudy beers), these machines operate in a fairly narrow window. Removal of fine solids at low concentrations is where they shine. But what to do when you want/need to separate a different stream? What if you wanted to recover beer from hop sludge or wort from trub?

Enter the Decanter Centrifuge

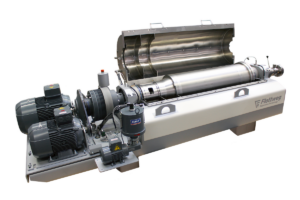

A decanter is a horizontal solid bowl centrifuge designed for high solids and difficult separation tasks. The decanter is a rotating cylinder with a screw/scroll inside to convey solids through. The rotational G-force separates the liquid from solids as the scroll conveys the solids toward the tapered end. The scroll is driven by an independent drive giving it a variable differential speed to maintain consistent solids discharge. The liquid is skimmed out via an adjustable impeller that can control the liquid depth inside the machine without stopping to make mechanical adjustments. The impeller (which is really a centripetal pump) and is sent away under pressure ranging from 0-28 psi. Bearing lubrication on a decanter can be a grease or air/oil system depending on the application and size of machine. In the brewery, these machines must have the highest level of hygienic design and protect the product passing through against dissolved oxygen pick up.

A decanter is a horizontal solid bowl centrifuge designed for high solids and difficult separation tasks. The decanter is a rotating cylinder with a screw/scroll inside to convey solids through. The rotational G-force separates the liquid from solids as the scroll conveys the solids toward the tapered end. The scroll is driven by an independent drive giving it a variable differential speed to maintain consistent solids discharge. The liquid is skimmed out via an adjustable impeller that can control the liquid depth inside the machine without stopping to make mechanical adjustments. The impeller (which is really a centripetal pump) and is sent away under pressure ranging from 0-28 psi. Bearing lubrication on a decanter can be a grease or air/oil system depending on the application and size of machine. In the brewery, these machines must have the highest level of hygienic design and protect the product passing through against dissolved oxygen pick up.

Recovery of Hot Wort from Trub/Whirlpool

Many breweries find that because of brewhouse design, wort cooling and transfer line, high gravity of wort or some other reason, they lose a percentage of extract between the whirlpool and the fermenter. A simple observation of this step or a bit of rudimentary math (wort into whirlpool – wort into fermenter = loss) often confirms this. If the whirlpool does not function as it should and too much extract is lost, brewers must look for ways to recover those losses.

One way to eliminate wort losses from the brewhouse is a trub decanter. By using a decanter, the trub can be separated from the wort, dewatered, and disposed of with the spent grains.

In most cases the decanting is done directly from the whirlpool. To do this a 45-degree cone (that takes up about 30% of the surface area of the tank bottom) is added to the vessel. The decanter is fed from this added cone and the recovered wort is sent back to the vessel through a return pipe that enters the whirlpool tangentially in the direction of the wort rotation. The return pipe ties into the vessel about halfway up the side to maintain a certain level in the whirlpool rotates and forms a trub pile in the middle. This is crucial to keep/promote the rotation of the wort inside the whirlpool. After the resting period and partway through the decanting step when the level reaches a certain point, the wort from the decanter pumps directly into the transfer line instead of into the vessel. The vessel level draws down and the solids concentrate in the center and as the last bit of trub is fed to the decanter, it is followed by de-aerated water to press out the recovered wort all the way to the fermenter.

In most cases the decanting is done directly from the whirlpool. To do this a 45-degree cone (that takes up about 30% of the surface area of the tank bottom) is added to the vessel. The decanter is fed from this added cone and the recovered wort is sent back to the vessel through a return pipe that enters the whirlpool tangentially in the direction of the wort rotation. The return pipe ties into the vessel about halfway up the side to maintain a certain level in the whirlpool rotates and forms a trub pile in the middle. This is crucial to keep/promote the rotation of the wort inside the whirlpool. After the resting period and partway through the decanting step when the level reaches a certain point, the wort from the decanter pumps directly into the transfer line instead of into the vessel. The vessel level draws down and the solids concentrate in the center and as the last bit of trub is fed to the decanter, it is followed by de-aerated water to press out the recovered wort all the way to the fermenter.

There are plenty of breweries that don’t have room below their whirlpool for a cone modification or just don’t want to cut into their brewhouse. In that case a buffer tank can be used between the whirlpool and the decanter. After the resting period, the wort can be pumped into the buffer tank and once the tank is partially full it begins to feed the decanter. In this configuration the wort from the decanter is sent directly to the wort cooler and then to the fermenter. If the brewery has space for such a set-up, this is a convenient way to go about it.

The solids separated in this process (trub) are fairly dry and granular. They can be pumped away but special care must be taken when selecting a solids pump to avoid plugging. Another way to move them is with an air conveyance system. This is usually done in larger commercial breweries where they already employ this particular type of technology.

The separated liquid flows through an open path back to the whirlpool or directly to the transfer line but in either case, the system uses a flow control valve on the return line to prevent foaming or cavitation inside of the decanter. Often it is adjustable from the HMI to provide between 0 and 28 psi of back pressure.

A decanter system must be able to be held accountable for its results (good or bad) and instrumentation is a big part of that. Things such as dissolved oxygen, turbidity, temperature and flow are constantly measured and logged to ensure quality of the wort and provide traceability should something go wrong.

When properly installed and utilized, a wort decanter system can cut wort losses from trub by as much as 97%. In breweries that make high abv beers or breweries that have very large brewhouses, there is usually plenty to be recovered which makes for a short ROI and a short ROI almost always makes a project successful.

Beer Recovery from Hoppy/Adjunct Tank Bottoms

In this industry beer is money and with so many breweries making so much hoppy, hazy, fruited or other adjunct added beers, there is a whole lot of beer/money going down the drain these days. Some breweries are doing very heavily dry hopped (think 1000 lbs. of pellets into a 120-bbl. fermenter!!!) beers that produce cellar losses in the 30-40% range. Anyone who has had to open the bottom of a fermenter to dump the sludge before sending the beer forward to filtration/centrifugation knows that not only is this sludge thick, but it’s also slow moving, voluminous and it does not play well with the downstream equipment. Most of the time this sludge is sent to the floor drain or to the brewery’s wastewater system, but every brewer sheds a tear as they watch their craft circle the drain instead of taking its rightful place in a glass or a can.

In this industry beer is money and with so many breweries making so much hoppy, hazy, fruited or other adjunct added beers, there is a whole lot of beer/money going down the drain these days. Some breweries are doing very heavily dry hopped (think 1000 lbs. of pellets into a 120-bbl. fermenter!!!) beers that produce cellar losses in the 30-40% range. Anyone who has had to open the bottom of a fermenter to dump the sludge before sending the beer forward to filtration/centrifugation knows that not only is this sludge thick, but it’s also slow moving, voluminous and it does not play well with the downstream equipment. Most of the time this sludge is sent to the floor drain or to the brewery’s wastewater system, but every brewer sheds a tear as they watch their craft circle the drain instead of taking its rightful place in a glass or a can.

This is where the decanter centrifuge comes in. A tank bottoms decanter system can separate anything (down to about 20 micron) that settles in the bottom of the fermenter, dewater it and return the recovered beer back to the fermenter. The system does not clarify the liquid. What is returned to the fermenter is a cloudy/hazy beer that is ready for further filtration (or just throw it in a can if that’s your thing, no judgment here).

The tank bottoms decanter system is very similar to the wort/trub decanter system in design but has a slightly higher level of automation and hygienic design due to its location in the brewery cellar.

There are many ways to operate the system but the most common is to feed the decanter from the bottom of the fermenter cone. It’s slow going in the beginning but once the sludge is flowing, the decanter will dewater the solids with relative ease. Unlike a disc stack centrifuge which is prone to plugging at high solids concentrations, the decanter can handle upwards of 75% solids by volume sludge. If you can pump it, this machine can separate it. The recovered beer is discharged under pressure by the decanter and sent back to the fermenter through the racking arm. Every 15-20 minutes the racking arm is turned, and the returning beer helps to wash the solids from the side of the cone into the feed line. For fermenters with no racking arm the beer is returned through the stand pipe which normally provides enough turbulence to force all of the solids into the feed line. During the optimization process it is sometimes necessary to open the fermenter and inspect for residual solids to ensure that the tank really is being emptied of the sediment.

There are many ways to operate the system but the most common is to feed the decanter from the bottom of the fermenter cone. It’s slow going in the beginning but once the sludge is flowing, the decanter will dewater the solids with relative ease. Unlike a disc stack centrifuge which is prone to plugging at high solids concentrations, the decanter can handle upwards of 75% solids by volume sludge. If you can pump it, this machine can separate it. The recovered beer is discharged under pressure by the decanter and sent back to the fermenter through the racking arm. Every 15-20 minutes the racking arm is turned, and the returning beer helps to wash the solids from the side of the cone into the feed line. For fermenters with no racking arm the beer is returned through the stand pipe which normally provides enough turbulence to force all of the solids into the feed line. During the optimization process it is sometimes necessary to open the fermenter and inspect for residual solids to ensure that the tank really is being emptied of the sediment.

The method of feeding and return is not the only variable to work out with this system. When to decant is also a big question when installing a decanter. Some breweries chose to run the yeast through the decanter before dry hopping. This not only makes final clarification easier, but it also provides a clean yeast paste that is around 30-35% dry matter that can be re used or sold since it is free of other particles. Other breweries dry hop with the yeast still in the bottom of the fermenter and run the sludge through the decanter together at the same time. Both ways are acceptable and yield good results. The same can be said for fruit and other fermenter additions. Typically, several techniques are tested before a final SOP is decided upon for each beer style.

Another question is whether to recirculate the recovered beer back into the fermenter or to do a complete transfer into an empty vessel. This is a great way to make sure every drop gets a turn in the decanter, but many breweries are limited by all of the tanks being full already, piping complexity or other factors. It is always worth trying if possible since the final result is a tank full of beer that has all been processed, no mixing with beer that has potentially not gone through the decanter.

Another question is whether to recirculate the recovered beer back into the fermenter or to do a complete transfer into an empty vessel. This is a great way to make sure every drop gets a turn in the decanter, but many breweries are limited by all of the tanks being full already, piping complexity or other factors. It is always worth trying if possible since the final result is a tank full of beer that has all been processed, no mixing with beer that has potentially not gone through the decanter.

The solids discharge from this process varies from pasty to very dry and granular depending on the nature of the solids. If it is only hops it will be dry and granular, if only yeast it will be paste but when it is a mixture the system will fluctuate between dry and pasty as those solids tend to stratify inside the fermenter. The decanter automatically adjusts the scroll speed to maintain steady torque loading and consistent solids discharge in this situation. With adjuncts like peanut butter powder, fruit puree or coffee grounds, there are also variations in consistency. There are 2 options for solids disposal. One is to use a progressive cavity pump below the machine to move the solids away. If this option is chosen, there is re-wetting water line installed in the transition chute between the decanter and the pump. A small amount of water is added back to keep the solids pumpable. If no pump is installed, then a hopper or tote can be placed directly under the decanter to catch the solids as they discharge from the machine. This option will require a bit more labor as the container will need to be changed/dumped from time to time but the solids will remain quite dry and be suitable for landfill, compost, or in some cases even animal feed.

This process also relies heavily on instrumentation and the most important in this case is the dissolved oxygen monitoring. It is always crucial in the cellar to prevent oxygen pick up. The beers life depends on it! Well, the shelf life that is. The machine is purged with a slow but steady flow of Co2 to ensure super low o2 pick up and dissolved oxygen meters are installed on both the inlet and outlet of the system to always monitor the levels. The system also utilizes turbidity measurement, flow measurement/totalization, and temperature monitoring. All this together allows for the lowest levels of dissolved o2 and consistent results both in terms of look and taste of the beer.

Summary

Decanter centrifuges are a work horse in the brewing industry. Whether separating trub from hot wort, dewatering heavy fermenter bottoms, dewatering filter media, treating wastewater or reprocessing spent grains, they can do it all. High solids applications are where they really shine and with most applications having a short ROI, it’s a sure bet that a brewery can benefit from this type of separation technology.

For more information on using centrifuges for beer production, follow this link.

High quality with increased efficiency

High quality with increased efficiency

Mechanical separation technology for the beverage industry – Beer brewers, winemakers, baristas, the list goes on – all want their drinks to be tasty. Every beverage manufacturer faces the same challenges, no matter what kind of beverage you have – be it beer or wine, coffee or tea. Flottweg is known for our reliability, flexibility, and individuality, and these qualities mean we are always at your side. Every day, our experienced specialists work on designing the best possible systems and solutions for our customers in the beverage industry. Combining “Made in Germany” value with high standards of hygiene and perfect product quality, we guarantee greater efficiency for your process.