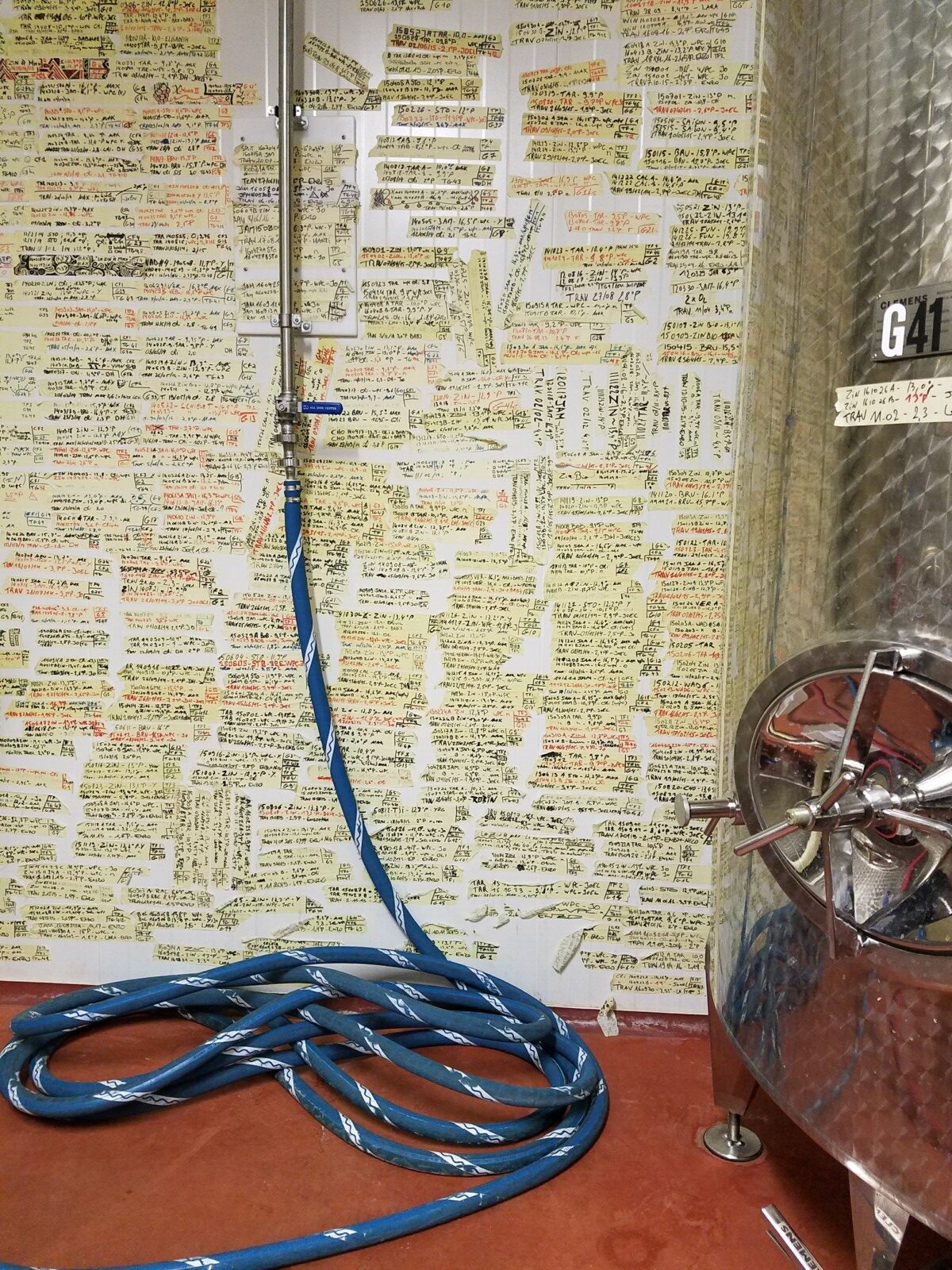

There is perhaps no more utilitarian object in a brewery than the lowly hose. Used to transfer beer from place to place, where gleaming stainless steel piping does not go, or clean systems, brewery hoses rarely get much love or thought. Yet the role they play is crucial and it’s important to give some thought before investing in them and how to maintain them.

Brewing Equipment featured expert topic supported by California Craft Brewers Association

The 2024 California Craft Beer Summit is the most important event of the year for California Brewers or anyone interested in building their business in the craft beer industry. The 2024 Summit will be held in Sacramento on March 12-14, 2024.

Know Your Usage

“Think of hoses as the arteries and veins of the brewery,” says Don Marcil of Stout Tanks and Kettles. While many breweries can get away with using 1.5 inch tubing and similarly sized tri-clamps for most transfer and cleaning tasks, it’s important to know the limitations and design specifications of your hoses. “You need to use the proper size for the proper application, heat, and chemical resistance,” he counsels. Be sure to confirm whether the hose can withstand proper temperature ranges and pressures along with managing cleaning agents such as caustics and acids. Also be aware that temperature increases also reduce the pressure limits of a hose.

For most uses, Marcil recommends the 1.5 inch insulated brewer’s hose, which is Stout Tank’s most popular option. “This is a food-grade, temperature-insulated, suction proof, pressure rated hose that is resistant to all sorts of CIP chemicals,” he says. “We recommend this equipment to breweries using seven plus barrel systems.”

You should also consider where the hose will be used within the brewery. There are versions designed to be resistant to crushing or getting twisted or kinked, which can come in handy for areas of high traffic and use.

For smaller breweries that require a more flexible option, Marcil also recommends a 1 inch insulated brewer’s hose with a 1.5 tri- clamp. “The insulation on these hoses provides temperature stability, which means that you can still move the hose while transferring hot liquids–though protective gloves should be worn–and that you can reduce carbonation loss and excess foaming while transferring cold liquids.”

Marcil also suggests smaller breweries consider using Santoprene hoses, which are a smaller, more affordable option that work well for hot-side transfers. “This material is food-grade and temperature rated, but it should not be subjected to high pressure environments,” Marcil says. “Santoprene is a great tool for transferring wort through the brewhouse. Typically, this hose is used on the outlet of pumps and not used for pump inlets as most pumps are strong enough to pull a vacuum.”

Hose Maintenance and Care

Maintaining a regular practice of inspecting your brewery hoses and addressing any issues is a crucial way to protect the quality of your beer and the safety of your employees. The Master Brewers Association of America (MBAA) recommends that brewers and cellar staff inspect hoses for damage or signs of wear prior to each use. Keeping maintenance records for hoses can also help track possible issues as well as give you a better understanding of how long your hoses are lasting under real world use conditions. Inspect the hose for excess wear, leakage near joints and fittings, and conduct regular internal inspections.

Marcil recommends teaching staff to treat hoses with care to lengthen their useful life. “Be attentive to ferrule ends as they will damage and bend if dropped against a floor,” he says. “Investing in hose bumpers is a good way to protect the ferrule ends and to allow water to flow underneath the hoses while cleaning.” These can include installing a Sani-Saver or other attachment that works to protect the ends of hoses in case they are dropped. Local companies may also offer internal inspection options, including using a scope to visually check for any damage on long runs of hose.

Regular cleaning and treatment of hoses also extends their life cycle. “All brewery hoses need a maintenance schedule and should be inspected regularly for blemishes, gouges, or cracks along the interior,” says Marcil. “Imperfections in the interior can harbor microorganisms that can create off flavors, product imperfections, or outright ruin your beer.” The MBAA recommends looking for any cuts, abrasions, blisters, or cracks on the hose, checking couplings for signs of corrosion or slippage, and noting whether the hose moves freely and maintains its flexibility.