By Christopher White, Ph.D., Sponsored by White Labs

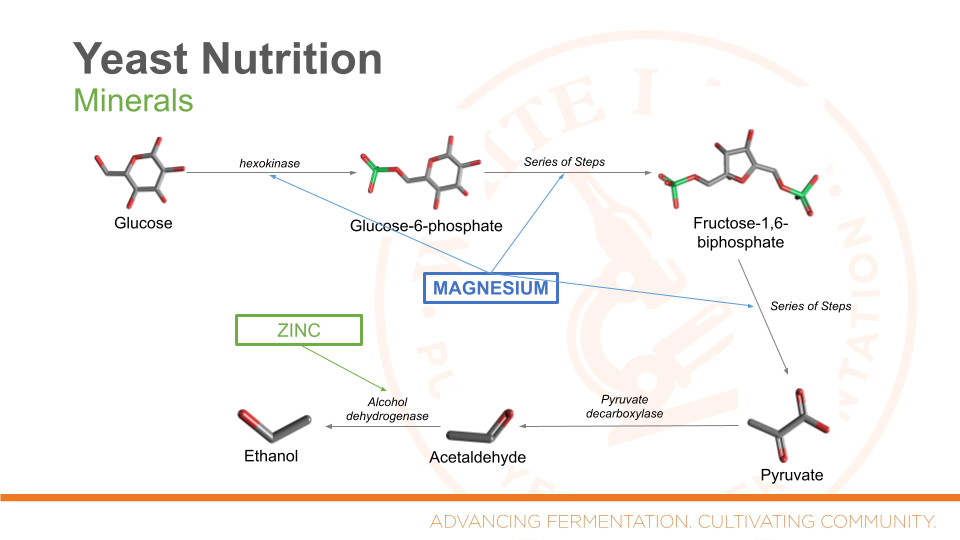

Yeast has a complex nutritional requirement. Conversion of wort sugar to alcohol is not just one chemical reaction, as was thought in the early nineteenth century. Hundreds of chemical reactions occur inside a yeast cell, requiring enzymes to catalyze different chemical reactions. Each enzyme also has specific mineral requirements for optimum performance. These chemical reactions produce alcohol, flavor compounds, energy for growth, cell wall compounds, and so on. If any of these reactions are compromised, there can be an effect on yeast health and fermentation performance, which has a direct impact on flavor.

Exact nutrient requirements vary between ale and lager strains, and for each strain within the species but in general, yeast needs an adequate supply of sugar, nitrogen, vitamins, phosphorus, and trace metals.

Zinc is one mineral that is often limited in brewers wort and is often not talked about. Zinc is of particular importance in the cell cycle (reproduction), and is a cofactor for alcohol dehydrogenase, the enzyme responsible for alcohol production.

The zinc requirement in beer fermentation can vary depending on the yeast strain, the type of beer being produced, and the composition of the wort. A typical requirement for yeast growth during beer fermentation is between 0.15 to 0.5 mg/L(ppm) of zinc. If the zinc levels are too low, yeast growth and fermentation can be negatively impacted, resulting in slower fermentation, incomplete attenuation, and undesirable flavor compounds. Supplementation of zinc into brewers worts generally has the effect of speeding up fermentation, as well as preventing stuck fermentations.

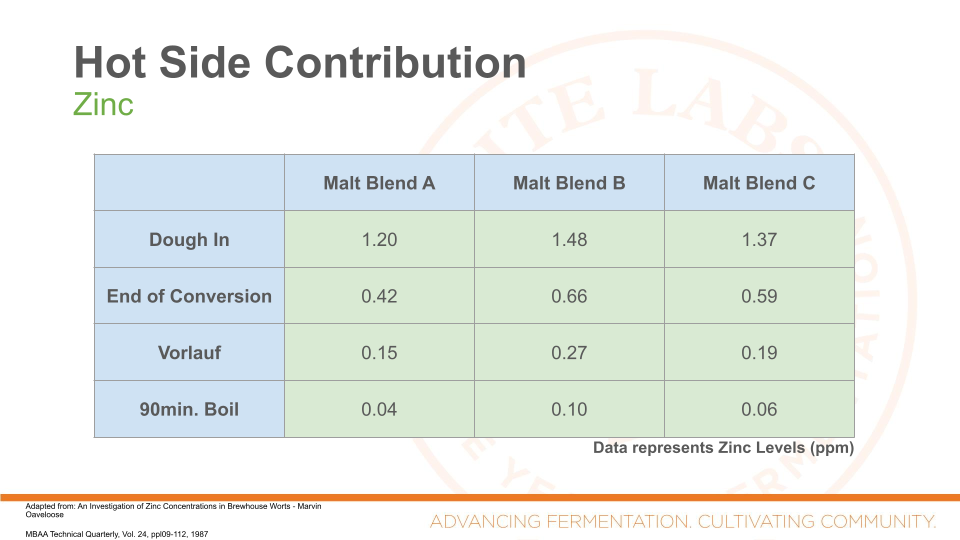

A key consideration when adding minerals is when they are added during the fermentation process. When the wort composition of minerals is technically sufficient, the bio-availability to yeast cells is in question. If added too early on the hot side, they can bind to trub and chelate or drop out of solution. Even when metals successfully enter yeast cells, they can be chelated within the cytoplasm. This is actually a natural defense mechanism for yeast, and is helpful for brewers to keep toxic metals from hurting fermentations.

Brewers can supplement the zinc levels in their wort by using zinc-rich brewing salts, such as zinc sulfate, or by adding nutrient blends that contain zinc, such as Servomyces.

Brewers can supplement the zinc levels in their wort by using zinc-rich brewing salts, such as zinc sulfate, or by adding nutrient blends that contain zinc, such as Servomyces.

Servomyces is an effective delivery method for zinc, and is produced in a patented process by which brewers yeast is grown in the presence of metal ions, including zinc and magnesium, and then dried and killed. When added to brewery fermentations in very minute quantities, the effect is dramatic to fermentation speed and to yeast performance/viability. The effect is much greater than with the addition of the same quantity of zinc salts.

Brewers can produce consistently great-tasting beers with optimal flavor, aroma, and alcohol content. Zinc can be the unsung (or sung) hero – try adding it to your next brew today! BUY NOW

Take Your Fermentation to the Next Level!

Take Your Fermentation to the Next Level!

White Labs’ PurePitch® Next Generation, an evolution of PurePitch® – the most superior and consistent yeast on the market – has been made even better with reliable cell concentrations and innovative packaging for ease of use and a pitch rate resulting in a foolproof fermentation every time. Find out more or order online at WhiteLabs.com