It’s a complex process to transform grains into refreshing, delicious beer. During production, a brewery’s step-by-step hot and cold processes influence the quality. Flottweg’s highly-efficient beer centrifuges meet the specific requirements of breweries while optimizing the entire process for maximum yields with the utmost level of quality.

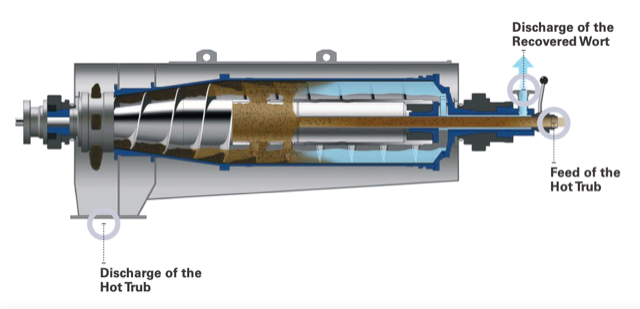

A beer’s character is already influenced in the brewhouse. Hot trub is created during whirlpooling when wort, hop debris, and precipitated protein are separated. Up to 75% liquid wort is still contained in hot trub. The Flottweg decanter separates the trub from liquid wort and uses pressure to return it to the hot wort clarification process. This minimizes wort losses and reduces the production costs per hectoliter of beer.

The Flottweg Simp Drive® automatically regulates the differential speed based on the scroll torque. This is how the Flottweg decanter automatically adjusts to different load conditions and always ensures maximum yields.

Dry Hopping

In aspiring breweries from the craft beer scene to an established technique in the entire brewing industry, dry hopping has developed from being more than just a trend in recent years. Adding hops during fermentation and storage allows for additional aromas, especially the essential oils of the hops to fully infuse into the beer. Hop pellets are dissolved in the beer during extraction and settle to the bottom of the tank to form sedimentation known as “spent hops.”

High-quality beer is contained in this hop sludge. In general, this sludge is separated from the beer by simply removing it (similar to yeast harvesting) before further processing (separation, filtration). In some cases, this removal of the hop sediment can lead to significant amounts of beer being wasted—around 5–20% of the tank content is typically lost.

The Flottweg decanter separates the spent hops from the liquid beer phase and uses pressure to return this to storage or bottling. This significantly reduces beer evaporation and relieves the load placed on downstream centrifuges and filtration. Dry hopping can be further automated with Flottweg decanter centrifuges. This allows for a reproducible production process and the highest quality of beer.

Beer Recovery From Surplus Yeast

The main purpose of yeast in the fermentation tank is to convert sugar into alcohol and various aromatic substances. After it has carried out this work in the tank, the yeast then settles to the bottom and in subsequent storage. Thanks to a high degree of separation, the patented Flottweg Sedicanter® provides two separate valuable materials from this suspension:

1. Beer that contains almost no yeast is returned to the further brewing process

2. A compact yeast cake that is used as animal feed or vitamin-rich food supplement.

This also means there is less brewery wastewater because more beer is sent back to the process.

The Flottweg Sedicanter® separates suspensions with fine or soft solids with an acceleration rate of up to 10,000 g. The flexibly adjustable impeller allows the Sedicanter® to be integrated into the existing process in the best way possible and always guarantees high yields.

Beer Clarification

Green beer produced in the fermentation tanks works its way into storage tanks. The upstream separator clarifies the green beer to ensure constant conditions in secondary fermentation. The required yeast cell counts are set by the brewers to define the secondary fermentation in the storage tanks.

How long the filter lasts will depend on the quality of the raw materials and the yeast load. Most of the yeast can be removed from the beer by the Flottweg Separator before filtration. This prolongs the filter life and means filter aids such kieselguhr do not need to be procured, handled, and disposed. Beer evaporation, cleaning, and wastewater costs are reduced.

When the Flottweg separator is used for final clarification, the beer’s turbidity is predefined before bottling. Turbidity measurements taken at the inflow and outflow monitor the yeast concentration regulating the turbidity adjustment in a fully automated manner to ensure uniform quality.

For more information about how decanters enhance the beer brewing process, please follow this link.