Can Depalletizer Automatic & Stainless Steel

New Product Ad posted 2 weeks ago in Other Packaging Equipment by Canadian Craft Solutions

Efficient, fully automatic stainless steel constructed and cost effective Depalletizer Canadian Craft Solutions has created a brewer designed Depalletizer with easy height adjustments and automatic sheet removal and storage. The Depalletizer accepts industry standard pallet sizes and offers windows for easy viewing. Fully Automatic Automatic can layer height control Simple HMI interface State of the art servo motors Standard conveyor Integrates with twist rinse Automatic layer sheet removal and storage Ball screw and linear rail pusher system Vertical travel drive by roller chain Easy height adjustment for level and can size Controls can be fully integrated with canning line as well as run as a stand-alone application All stainless-steel construction

New Product Ad posted 3 days ago in Other Packaging Equipment by Pio (Tim Piotrowski)

Systems was purchased to meet requirements of the canning line we purchased, but our existing compressor was able to supply adequate air. Air Compressor NEVER USED; still on the pallet. Ready to ship. This package can be built from Air Compressors Direct for $20,950 -- Save ~$3k Package Offer Price: $18,000 Buyer to arrange freight, seller will load. Air Compressor (Rotary Screw) Atlas Copco GA7VSD+ FF API 460V (3-phase) 10hp - max 46 CFM, max 175 psi variable speed drive delivers 15.2-46.4 CFM @ 80 PSI; up to 30.1 CFM @ 181 PSI 62 dBA Integrated Air Dryer (Save $2,267) R410a refrigerant 25" W x 39" L x 56" H; 591 lbs two minor scratches/dents from the manufacturer (passing along the $1k cosmetic savings) From the manufacturer: The revolutionary new GA 7-15 VSD+ is packed with innovative features that increase its efficiency, cuts its energy consumption, lowers its noise levels,...

New Product Ad posted 2 months ago in Other Packaging Equipment by Alpha Brewing Operations

-For a Limited Time Only- Lotus Beverage Alliance is celebrating the 4th of July with 15% off select canning lines! Reach out now to take advantage of this offer. Compass 25 - Compact and Consistent This entry-level canning system is much more powerful than the price tag would have you believe. Packaging up to a rate of 25 cans per minute means, the Compass 25 is uniquely positioned to bring your business to the next level. With a "double barrel" fill station design, your beverage picks up less dissolved oxygen and greater shelf-life with each canning run. Specifications: 304 Stainless Steel Mobile frame with casters. Ultra-compact footprint = 48" L x 28" W x 66" H 3 fill stations, each with 2 fill tubes. 316 Stainless Steel fill head design increases fill speed. CO2 purge in fill head assembly. Only canning lines that purges while it fills. (Updated on 6.13.2023)

New Product Ad posted 2 months ago in Other Packaging Equipment by Alpha Brewing Operations

Pack-off is the most labor-intensive aspect of canning. The “Mini-Gun” 4 – 6 pack carrier applicator offers instant return on investment! The Mini-Gun is the quietest, smallest, most efficient applicator in the industry. – Less than 1 full load amp (4 amps with conveyor). – Less than 2 cfm compressed air. Wait till you see the price! The Mini-Gun pairs perfectly with the Beer Cannon series of canning lines from Alpha or fit to any existing canning system. We have a new web site – check it out: www.alphabrewops.com and request a quote. Cheers!

New Product Ad posted 3 months ago in Other Packaging Equipment by QuantiPerm

Direct to filler option. Carbonate-and-Fill from dead-flat to up to 4 v/v and line speeds up to 25 gpm. Send product directly to a filler, with no intermediate tanks! The system employs a small buffer tank to consistently supply your packaging line in the face of intermittent filler interruptions. Just specify how much carbonation you want and let the system go! Use for up to 270 cans per minute!

New Product Ad posted 4 months ago in Other Packaging Equipment by IDD Process & Packaging, Inc.

The recommended minimal standards when operating an IDD 'PurePass' Flash Pasteurization Systems are outlined below. They are intended as a guide and in no way over‐ride or supplant EPA, FDA and HACCP standards required by law where applicable. The process and packaging of product can be broken down into the following areas: Product – Beer Product preparation – batching, blending, carbonating equipment Package materials in contact with the product (i.e. bottles, cans, crowns, lids and caps) Product 'Flash Pasteurization' Package handling and filling equipment Product preparation and packaging areas Personnel and personal hygiene 1. PRODUCT used in the final product must be maintained in a clean and sanitary environment to prevent microbial growth in the product. Additives, etc. should be in a dry, cool area and liquids in a cold room at <38°F/3.5°C to prevent mold, fungal and bacterial growth. Frozen concentrates should be thawed at low temperature in the...

New Product Ad posted 4 months ago in Other Packaging Equipment by IDD Process & Packaging, Inc.

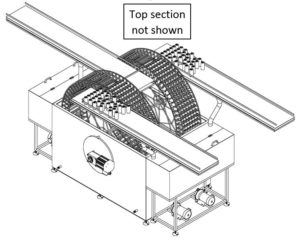

We listen, learn and respond... Being advocates of pasteurization, we at IDD have for years designed and manufactured a full range of fully automatic Flash Pasteurization systems to meet the needs of the beverage industries large and small. There is an abundance of Tunnel Pasteurization systems manufacturers available in the market for those that feel more comfortable with in-package pasteurization, but nothing to suit small footprint, inline processing and efficiency for the craft industries can lines doing up to 75 cans per minute. We have thought outside of the box and come up with a box to keep the footprint small, the energy consumption low and the efficiency high. We’re calling it the Rotary Pasteurizer or RP1 (35 cans per minute) and RP2 (70 cans per minute) Service Features & Benefits *Compact – 12’L x 9’W x 8’H *35 and 70 CPM nominal outputs *Up to 100 PU’s *Temperature...

New Product Ad posted 5 months ago in Other Packaging Equipment by Palmer Beverage Systems

Can Warming Tunnel Stainless Steel Construction Compact Design Serpentine Conveyance Control System with Status Light Hot Water or Steam Optional Stainless Steel Belting Optional Discharge Blower

New Product Ad posted 5 months ago in Other Packaging Equipment by Palmer Beverage Systems

Our automatic beverage blending and carbonation system is designed for the production of carbonated and non-carbonated beverages. The 3-in-1 skid-mounted space-saving unit allows to de-aerate, blend and carbonate various soft-drinks with the utmost precision and consistency at outputs from 3,000 to up to 80,000 liters per hour. Carbonation performance of up to +22ºC (+72ºF) with 5 v/v CO2 enables a broad range of products >95% total CO2 efficiency DOWNLOAD BROCHURE

New Product Ad posted 6 months ago in Other Packaging Equipment by Cask Global Canning Solutions

The Cask MCS V2 is a simple to use, compact canning system geared for packaging every type of craft beverage in any can format. The MCS V2 is the most cost-effective distribution quality canning system available for crat beverage markers. Speed: 10 cans/min; 25 cases/hour Footprint: Compact Footprint: 1' x 4' / 4 sq ft Growth: Geared for helping craft beverage makers get their product into more hands quickly and easily, and allowing them to grow their business Filling Tech: Cask offers the only filling technology on the market that can create and manipulate foam for optimal protection against oxygen Any Beverage: Higher carbonation capabilities (3.2 vol CO2) & all Stainless Steel components and CIP capabilities enable cross-over of any craft beverage BOOK A DEMO OR QUOTE Package any can format:

New Product Ad posted 8 months ago in Other Packaging Equipment by Criveller Group (Healdsburg, CA and Niagara Falls, ON)

The Mini Line 01 and Mini Line 02 labelers are able to apply front and back labels from the same roll to cylindrical containers, or two separate rolls (Mini Line 2 only). Can be an integral part of various bottling lines. CHARACTERISTICS: Output: 700 bottles/hour Unit capable to work with bottles with diameter ranging from 60mm up to 120 mm; unit can work with different containers May apply wraparound labels Machine built in accordance with C.E. regulations Motor: 220 volt/single phase/60 Hz OPTIONS: Date coding device Square bottle kit Kit for spot detection Kit for pre-labeled bottle Small bottle kit Tapered bottle kit